Blog

Enhancing Sugar Processing Equipment Efficiency with Sugar Mill Oil

“`html

Enhancing Sugar Processing Equipment Efficiency with Sugar Mill Oil

Estimated reading time: 5 minutes

Key takeaways:

- Understanding the types of sugar mill oil and their properties.

- Recognizing the benefits of using specialized oil in sugar processing equipment.

- Learning proper application techniques for optimal performance.

- Reviewing successful case studies demonstrating oil effectiveness.

Table of contents:

- Types of Sugar Mill Oil

- Benefits of Using Sugar Mill Oil

- Application of Sugar Mill Oil in Processing Equipment

- Case Studies or Success Stories

- Conclusion

- FAQ

Types of Sugar Mill Oil

In sugar mills, commonly used oils include mineral oil, synthetic oil, and food-grade oil. Each type of oil has distinct properties, such as viscosity, thermal stability, and corrosion resistance. Mineral oil is known for its affordability and availability, while synthetic oil offers high thermal stability and reduced friction. Food-grade oil is crucial for maintaining food safety standards in sugar processing. The suitability of each type of oil depends on the specific equipment and its requirements.

For more information on the properties of different types of sugar mill oils, visit: here.

Benefits of Using Sugar Mill Oil

Using specialized oil in sugar processing equipment has several advantages:

- Increases efficiency

- Reduces friction

- Prolongs the life of equipment

Research findings indicate that quality oil positively impacts equipment performance and maintenance costs. By investing in high-quality sugar mill oil, sugar mills can enhance their production processes and reduce operational expenses.

Application of Sugar Mill Oil in Processing Equipment

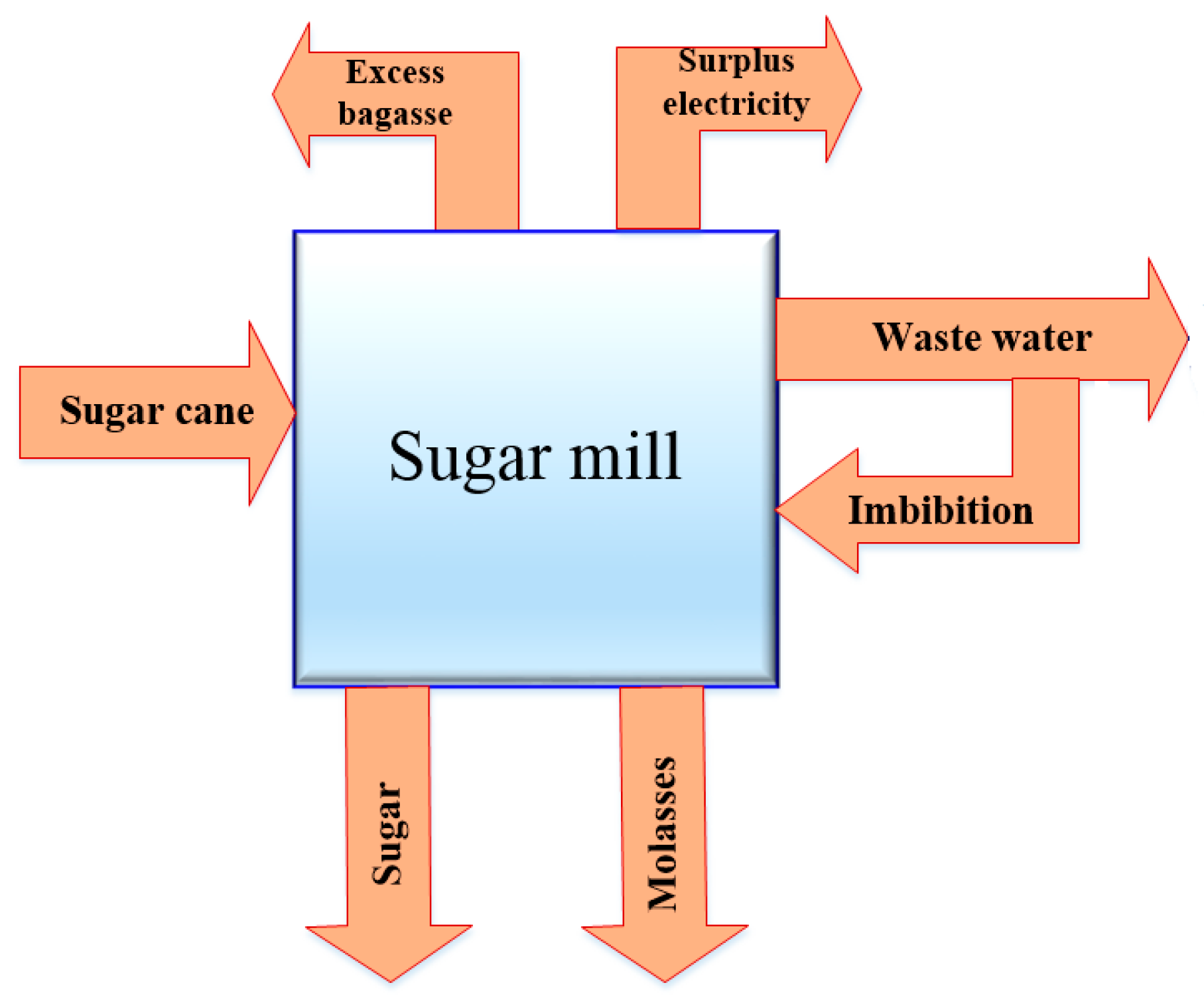

Sugar mill oil is applied to various equipment in sugar mills, including pumps, gearboxes, and turbines. Proper application of oil improves the performance and reliability of these machines. Research shows that following best practices for oil application is crucial for optimal equipment operation. By applying sugar mill oil correctly, sugar processing equipment can operate efficiently and sustainably.

Case Studies or Success Stories

Real-life examples of sugar mills using specific oils demonstrate the positive results achieved. Increased production, reduced downtime, and improved equipment performance are some of the benefits reported. Industry experts emphasize the effectiveness of using quality oil in sugar processing equipment. References to reputable sources or studies further support the advantages of using specialized oil in sugar mills.

Conclusion

In conclusion, using the right oil in sugar processing equipment is crucial for maximizing efficiency and longevity. Sugar mill oil plays a significant role in enhancing equipment performance and ensuring smooth operations in the sugar industry. By investing in quality lubricants, sugar mills can improve their production processes and reduce maintenance costs.

Call to Action: For more information on our sugar mill oil products and services, contact us today. Visit our website for a range of resources and products related to sugar processing lubricants. Enhance your sugar processing equipment efficiency with our high-quality sugar mill oil.

“`