Blog

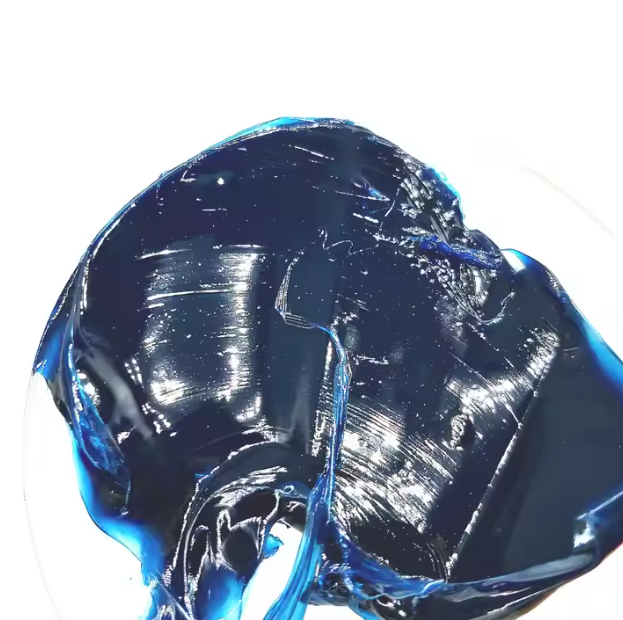

Rollester High Temperature Grease – Keep Your Machinery Moving Smoothly Even at Extreme Temperatures

Rollester High Temperature Grease – Keep Your Machinery Moving Smoothly Even at Extreme Temperatures

In the harsh environments of heavy machinery and industrial operations, maintaining peak performance is essential. That’s where Rollester High Temperature Grease comes into play. Engineered to withstand extreme conditions, this grease is a game-changer for industries requiring durability and reliability under the most challenging circumstances. Let’s delve into why Rollester High Temperature Grease should be your go-to choice.

Understanding the Basics of Industrial Lubricants

Industrial lubricants are crucial components in machinery operations, designed to reduce friction, prevent wear, and ensure optimal performance. Among various types of industrial lubricants, greases stand out due to their consistency and ability to remain in place at high temperatures, making them indispensable in many industrial applications.

What Makes Rollester High Temperature Grease Special?

Rollester High Temperature Grease is manufactured with a blend of high-grade base oil and advanced additives that offer unparalleled protection and performance. Here’s why it stands out from the crowd:

- High Mechanical Stability: This grease maintains its integrity under constant motion and mechanical stress.

- Good Sealing Properties: It effectively seals out dust, moisture, and other contaminants, ensuring long-lasting protection.

- High Thermal Resistance: With a drop point of up to 380 degrees Celsius, this grease excels even in the hottest operating environments.

- Water Resistant: Designed to repel water, preventing rust and corrosion.

- Corrosion Resistant: Its superior formula prevents metal surfaces from corroding.

- High Pressure Load Capacity: Ideal for high-pressure applications where traditional oils would fail.

Applications and Ideal Uses

Rollester High Temperature Grease is versatile and can be used across various industrial sectors where extreme temperatures and demanding conditions pose challenges. These include:

- Metallurgical Industries

- Paper Manufacturing

- Metal Processing

- Steel Rolling Mills

- Rolling Bearings

- Food Industries

- Pollution Control Equipment

- Power Generation Plants

Rollester High Temperature Grease ensures smooth and prolonged operation of machinery in these industries, significantly reducing maintenance costs and downtime.

Why Choose Rollester?

Choosing the right lubricant is critical for machinery longevity and efficiency. Rollester High Temperature Grease offers several compelling reasons to make it your primary choice:

Its high-grade composition ensures superior performance, and the extensive testing and quality control processes guarantee reliability.

Rollester adheres to ISO9001:2015 quality standards, ensuring each batch meets the highest industry benchmarks. Furthermore, the flexibility in choosing customized NLGI grades makes it suitable for a wide range of applications. For businesses seeking a robust solution to protect their investments, Rollester High Temperature Grease is the perfect choice.

FAQ

Can I use this grease in all temperatures?

This grease is designed specifically for high-temperature applications, typically performing well up to 380 degrees Celsius. It’s not recommended for very low temperatures. Check with our technical support for specific recommendations based on your operational conditions.

Is it safe to mix different types of grease?

No, it is not advisable to mix different types of grease. Doing so can compromise the performance and stability of the lubricant, leading to increased wear and tear on your machinery.

How do I store this grease properly?

To maintain the integrity and performance of Rollester High Temperature Grease, store it in a cool, dry place, away from direct sunlight. Keep containers sealed tightly to prevent contamination with water or other substances.

Ready to elevate your machinery’s performance? Experience the reliability and longevity that comes with Rollester High Temperature Grease. Order now and see the difference for yourself!